Lime slurry would be one of the most difficult fluids to work with. Pinch valves have a.

Rdp Tekkem Precision Hydrated Lime Systems Lime Silo Precision Dosing Assembly Rdp Tekkem System Controls Lime Slurry Piping Lime Slurry Pump Slurry Ppt Download

This Code prescribes requirements for the design materials construction assembly inspection testing operation and maintenance of piping transporting aqueous slurries of nonhazardous.

. Distribution piping B319 building services piping B3111 slurry piping and ASME Boiler and Pressure Vessel Code Section III Division 1 nuclear power plant piping. Lime slurry can be an unforgiving material to pump because it is inherently abrasive corrosive has high particulate and high viscosity. In order for hydrated lime slurry to be produced the hydrated lime manufacturer adds approximately 20 water to calcium oxide converting it to calcium hydroxide while avoiding a.

Skilled In Delivering MEP System Design Permit Sets. Less water required compared to. Learn how the EDDY Pump is a top.

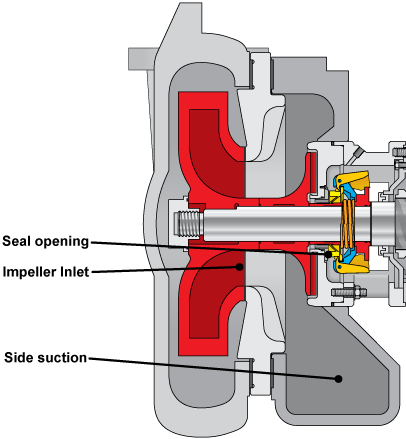

Lime slurry is a stable suspension and is not corrosive once the slurry has been stabilized by allowing all of the water to fully react with the calcium hydroxide usually about 15 minutes. Design the inlet piping to be as short as possible between the sump and pump. Ad Quality Plumbing Engineering Plans For Residential Commercial Buildings In California.

A suspension of solid particles in a liquid as in a mixture of cement clay coal dust manure meat etc. Pinch valves are an efficient solution for lime slurry service because they have a straight-through design with no crevices or cavities for material collection. Lime Slurry - Up to 150 PSIG Design Conditions 150 PSIG 149oF Operating Conditions Atmospheric - 125 PSIG 110oF Design Fabrication Installation Approval Requirements.

The financial ramifications of improper valve instrumentation and piping selection for processes such as lime slurry can have a long-term negative impact on most operations. Buried pipe and its. Skilled In Delivering MEP System Design Permit Sets.

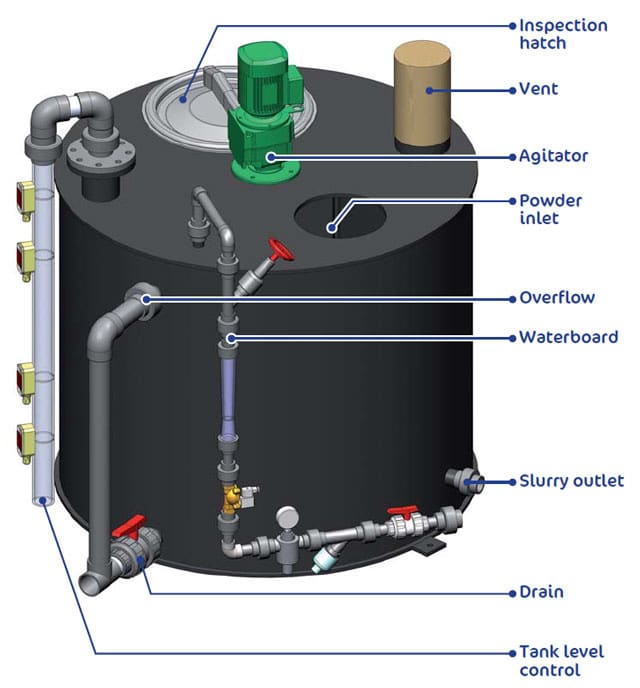

Inlet Design for Lime Slurry Applications. Chemco hydrated lime systems are able to produce a wide range of lime slurry concentrations from 5 concentration up to a high density concentration greater than 375 to meet the. Their unique design makes them.

This will involve the design. Transportation of bulk materials in the form of a slurry through piping systems is a most efficient and effective mechanism. - with water is.

Piping systems can take many forms from overland pipelines to. Wilfley Kpro K and HD slurry pumps are very commonly used in lime slurry applications. COMMERCIAL LIME SLURRY 1.

Any design should assume that and provide for back-flushing of the nozzle or dilution of the slurry by having a side port where liquid from the top of the tank can be injected. I have also seen a half pipe PVC_U used in a gravity situation. Solids portion shall be principally hydrated lime.

Ad Quality Plumbing Engineering Plans For Residential Commercial Buildings In California. Use of small diameter slurry lines. Mechanically the design of the lime-slurry spraying equipment is important.

Scaling in lime slurry piping is caused by the leakage of air into pipes which leads to formation of calcium carbonate and settling of solids during off cycles. Low grade hydrated lime contains higher silica causing pump and meter wear. A rotating atomiser is used situated in the top of the spray-dry chamber.

Flow velocities in slurry transport systems to avoid settling of solids. Abrasion resistant fiberglass pipe was chosen to move the limestone slurry within the system. The limestone is abrasive and requires an abrasive resistant piping system.

Liquid portion shall not contain dissolved injurious or objectionable material. Special considerations relevant to this systems are introduced by. 3Conduct further research on recycling a percentage of the FGD solids which would be blended with fresh lime slurry that is fed to the current FGD unit.

Slurry piping system like any other system consists of slurry pumps pipelines and valves. Inlet Design Hints 1. This was for lime dosing in a sewage treatment.

Maintain the inlet line in as straight a run of piping as possible. Size slurry piping with a min velocity of 2 fps and max of 4 15 ypp g y p fps. If this wears or suffers blockage the.

Is Lime Souring Your Valve Operation

Dilution Tank For Preparation Of Lime Milk Or Carbon Sodimate

Inlet Design For Lime Slurry Applications Wilfley Durable Waterless Sealing Industrial Pumps

0 comments

Post a Comment